Viet Water is one of the reputable units, located at 339 Pham Van Bach, Ward 15, Tan Binh District, Ho Chi Minh City. With tax code 0312931928, the company provides Deerfos MBR membrane filters, committed to ensuring quality and reasonable prices.

The MBR (Microfiltration Membrane) is an important component in water filtration systems, helping to remove small impurities, bacteria, and micro-sized particles. This helps make the water clean and safe for use.

The structure of MBR filter membrane consists of the following main components:

Filter membrane: This is a crucial component of the system, MBR filter membranes are typically made from high-quality materials such as polyethylene, polypropylene, or polyvinylidene fluoride. This membrane has very small pore sizes, which help retain most solid particles and bacteria in wastewater.

Wastewater tank: Wastewater from the treatment process is pushed through a filtration membrane in this tank, helping to separate liquid and solid substances.

Swim filtration system: To ensure maximum efficiency, MBR filtration membranes are often accompanied by a swim filtration system, which helps prevent clogging and enhances the self-cleaning capability of the system.

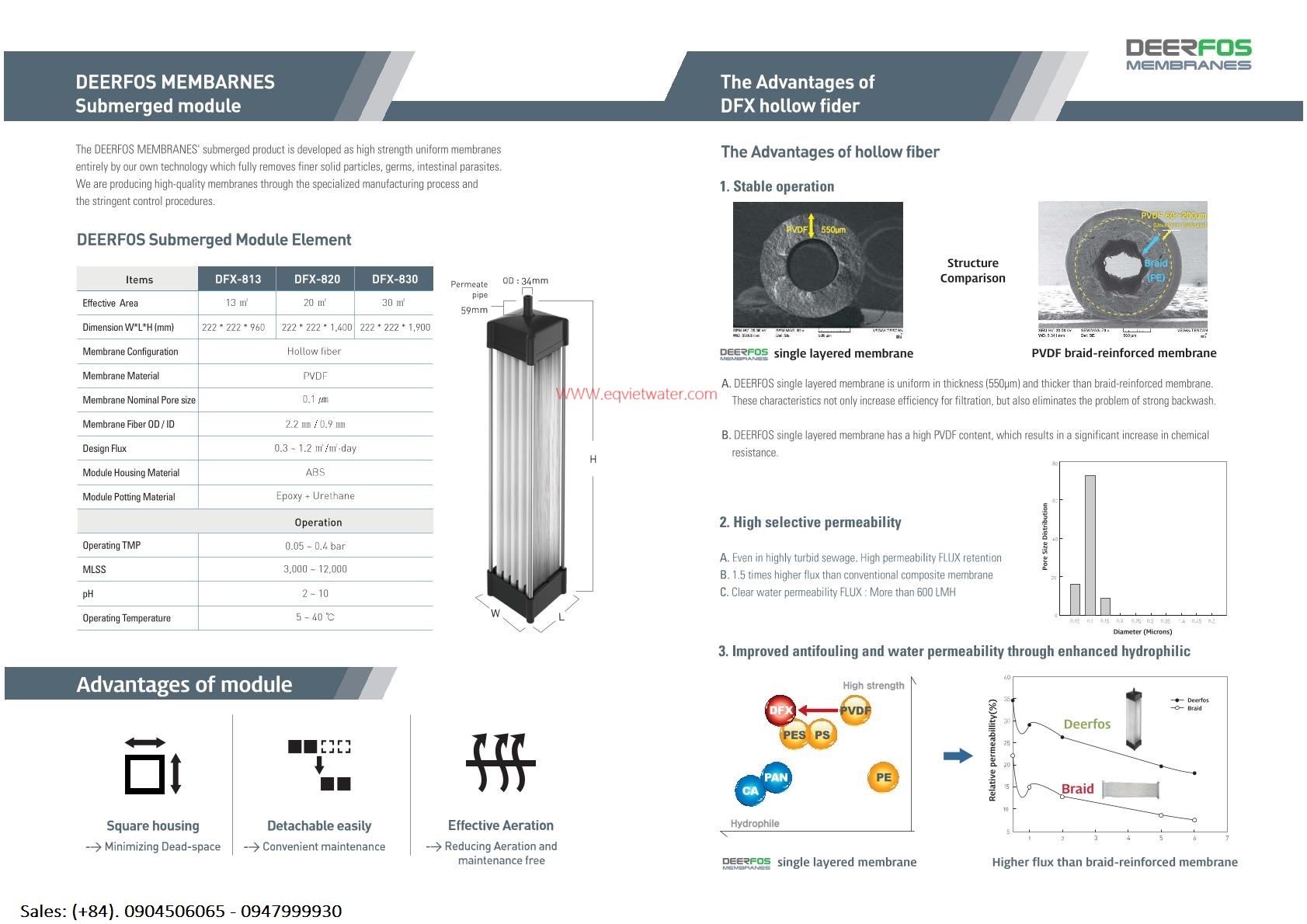

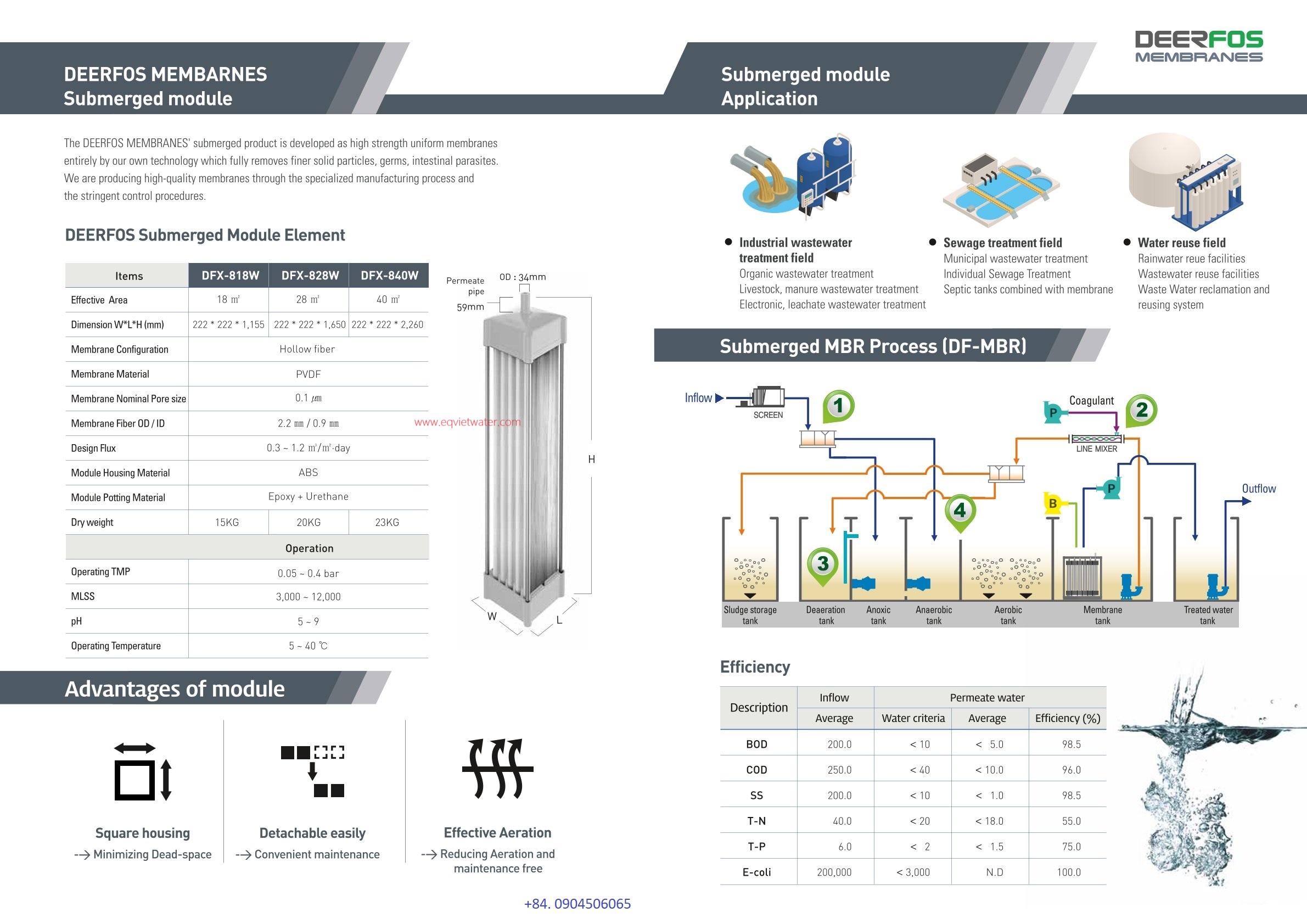

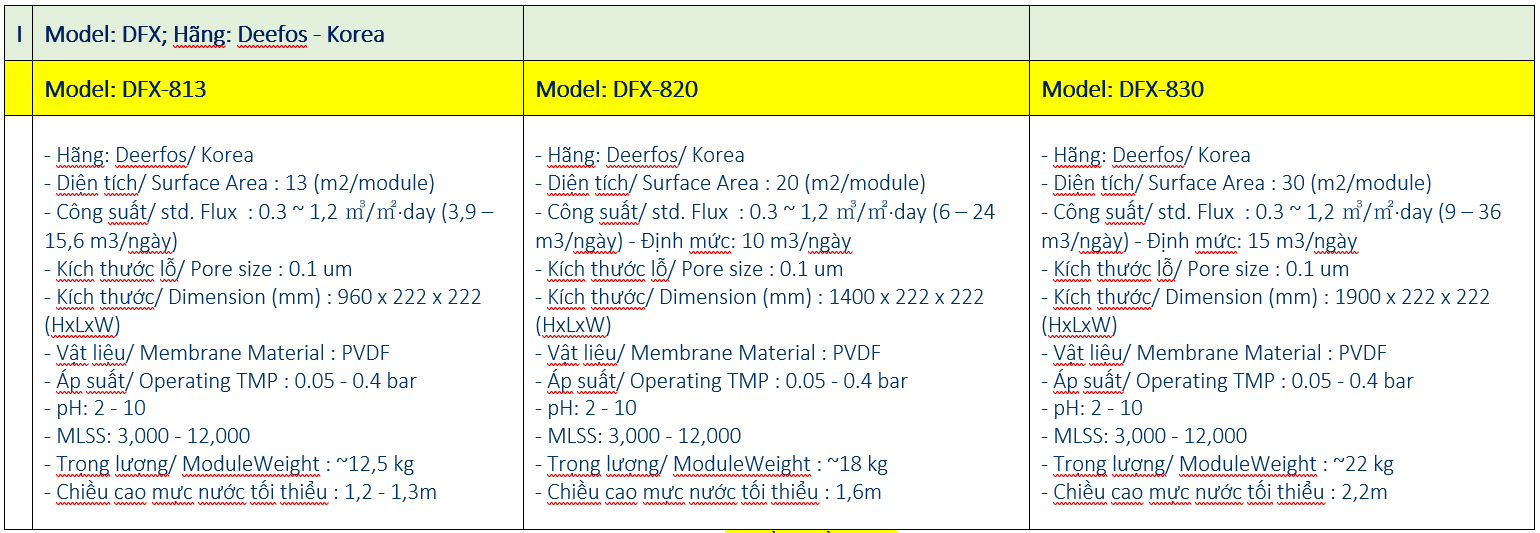

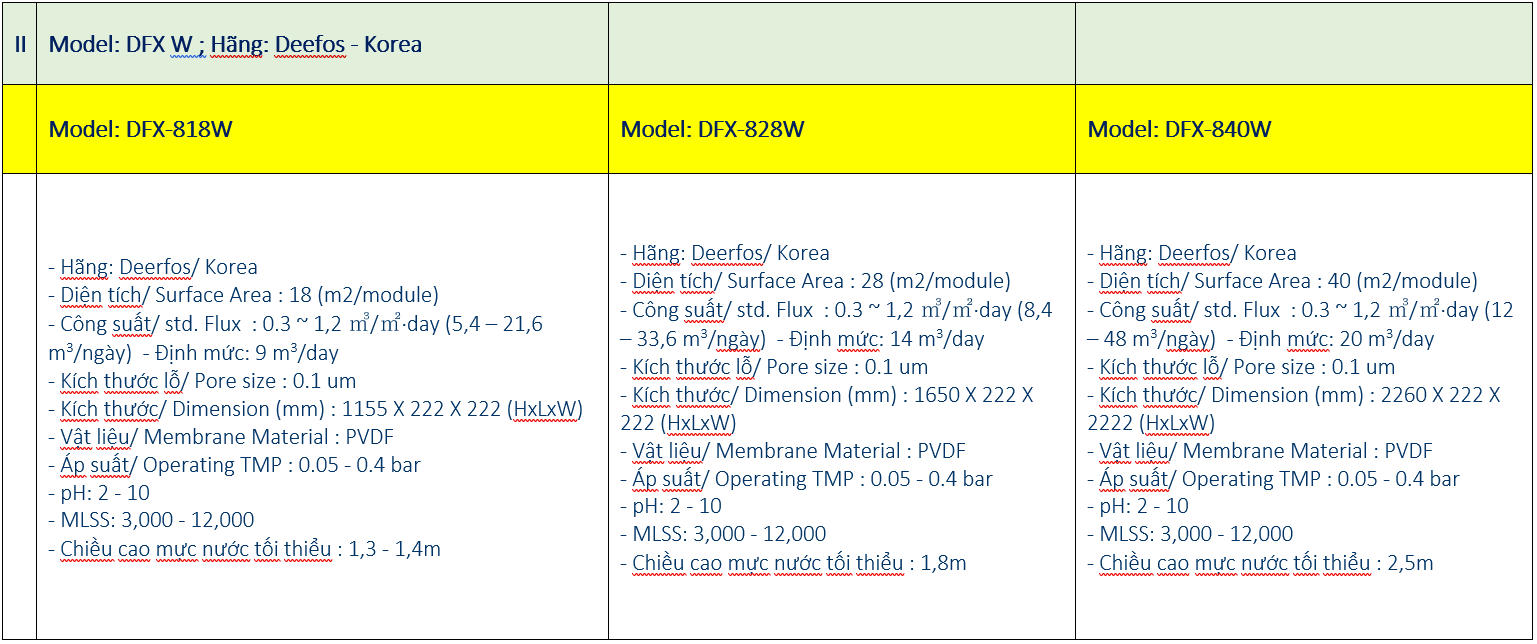

- The new generation Deerfos (Korea) membrane filter with compact design for easy installation and operation, and high durability.

- Application: Wastewater treatment

- Origin: South Korea. DEERFOS MBR membrane filters are manufactured in South Korea and certified by South Korean authorities.

- For pricing and installation consultation, please contact: (+84) 0904506065

Installation and treatment efficiency:

- Application: Wastewater treatment

- Membrane pore size: 0.1um - with treatment efficiency up to 98.5%

Principle of Operation of MBR Membrane

The operation of MBR membrane is based on the fundamental principle of membrane filtration within a closed space. As wastewater is pushed through the membrane, liquid is retained and solids are separated, resulting in cleaner treated water. This process can occur continuously, helping to maintain stable wastewater quality.

Advantages of MBR Membrane

MBR membrane offers several important advantages, including:

High filtration efficiency: MBR can effectively remove solids and bacteria, producing high-quality treated water.

Space-saving: Compared to traditional treatment methods, MBR requires less space, thus saving area.

Capability to handle fluctuating wastewater: MBR can process wastewater with varying quality and quantity, making it suitable for various applications.

Disadvantages of MBR Membrane

However, there are also limitations to consider when using MBR membrane:

High capital investment costs: Installing and maintaining an MBR system requires significant upfront investment, which can be a challenge for projects with limited resources.

Technical expertise requirements: Operating and maintaining MBR membranes demand deep technical knowledge and professional skills.

Comparison of MBR with RO

When comparing MBR with Reverse Osmosis (RO), there are important differences to note:

Treatment goals: MBR primarily focuses on removing solids and bacteria from wastewater, while RO concentrates on filtering source water to produce high-quality drinking water.

Filtration efficiency: RO can remove unwanted chemicals and ions, whereas MBR mainly retains solids and bacteria.

Comparison of MBR with UF

Comparing MBR with Ultrafiltration (UF) also highlights noteworthy points:

Pore size: UF employs larger filter pores than MBR, helping to block larger particles.

Costs and efficiency: Although UF often has lower initial investment costs, MBR typically offers higher filtration efficiency and is suitable for applications requiring high water quality.

While MBR, RO, and UF each have their own advantages and disadvantages, the choice between them depends on the specific purpose of the project and water treatment requirements.

Applications of MBR Membrane

MBR membranes have diverse applications in various fields, from household water treatment to industrial applications. Below are some common applications of MBR membranes.

MBR membrane filtration is widely utilized in industrial wastewater treatment systems to remove solids, bacteria, and other organic impurities from wastewater, producing cleaned water that can be reused or discharged without causing pollution.

In urban wastewater treatment systems, MBR membrane filtration improves the quality of treated water and reduces the land area required for conventional filtration tanks.

In the food and pharmaceutical industries, MBR filtration membranes are utilized to produce premium clean water, ensuring safety and quality throughout the manufacturing process.

Treatment of Seawater and Brackish Water:

MBR filtration membranes are commonly integrated into seawater and brackish water treatment systems, aiding in the removal of salt and other impurities to create clean and safe drinking water.

Household Drinking Water:

In household applications, MBR filtration membranes are used in domestic water filtration systems to provide clean, safe, and palatable water for all family members.

Chemical Industry:

In the chemical industry, MBR filtration membranes can help remove sediments and impurities from raw water, ensuring cleanliness and safety in the manufacturing process.

Oil and Gas Wastewater Treatment:

In the oil and gas industry, MBR filtration membranes are applied in wastewater treatment to reduce the risk of environmental pollution and meet environmental protection standards.

Conclusion:

MBR filtration membranes not only bring significant benefits in improving water quality but also play a crucial role in environmental protection and meeting the increasing demand for clean and safe water in various fields.

Contact Deerfos Korea's MBR Filtration Membrane product consultation hotline at: (+84)904506065.